- World’s largest extensometer manufacturer

- Unrivaled quality

- Responsive – talk to our experts anytime

- Broadest product line anywhere

- Expertise – in both testing and extensometers

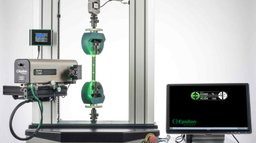

Over forty years of experience have gone into the development of Epsilon’s products. At their facility in Jackson, Wyoming, they design and build extensometers for testing around the world.

Extensometers are available for testing almost all engineering materials, including metals, composites, plastics, ceramics, elastomers, geomaterials (e.g. rock, concrete, and asphalt), and biomaterials including bone.

There are models for tiny and delicate samples, including relatively fine wire, up to massive metal samples and large rock cores. The huge variety of models covers nearly every type of test as well, including: tensile, compression, bend, fracture mechanics, and cyclic strain controlled tests like low cycle fatigue. Many of our extensometers are capable of relatively high frequency operation as well.

EXTENSOMETERS

EXTENSOMETERS

EXTENSOMETERS

GAGES

DEFLECTION GAGES

EXTENSOMETERS

EXTENSOMETERS

EXTENSOMETERS

EXTENSOMETERS

EXTENSOMETERS

Specialized extensometers for

EXTENSOMETERS

FOR EXTENSOMETERS

ELECTONICS

FOR EXTENSOMETERS

FOR EXTENSOMETERS

An extensometer is a precision measuring instrument used in materials testing to accurately measure changes in length or strain of a material specimen under mechanical loading. It provides essential data for evaluating the mechanical properties and deformation behavior of materials.

Extensometers are typically attached to the surface of a test specimen, and as the specimen is subjected to mechanical stress, the extensometer measures the resulting changes in length or strain. These measurements are then recorded and analyzed to determine the material’s mechanical characteristics.

There are various types of extensometers, including clip-on extensometers, contact extensometers, non-contact extensometers, and strain gauge extensometers. Each type has its specific applications and advantages.

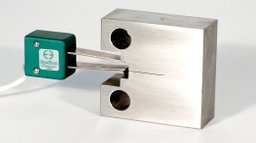

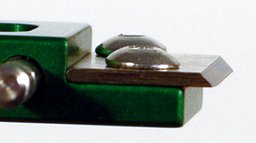

Clip-on extensometers are attached directly to the sides of a test specimen. They typically use contact arms or clips to measure the change in distance between two reference points on the specimen as it is deformed.

Contact extensometers make direct physical contact with the surface of the specimen during the test. They use mechanical arms or pins to measure the elongation or compression of the material.

Non-contact extensometers use optical or laser technology to measure the deformation of the specimen without physically touching it. They are ideal for testing delicate or sensitive materials.

Strain gauge extensometers use strain gauges attached to the surface of the specimen to measure changes in strain. These extensometers are highly accurate and can be used for various materials and test conditions.

Extensometers provide precise and reliable measurements of strain or deformation, allowing researchers and engineers to understand a material’s mechanical properties, such as Young’s modulus, yield strength, and elongation.

Extensometers offer several advantages, including increased accuracy and repeatability of test results, improved data quality for material characterization, and better control over the testing process.

Selecting the appropriate extensometer depends on factors like the material type, test conditions (temperature, loading rate), required accuracy, and budget constraints. Consulting with experts and understanding the specific testing requirements is essential for making the right choice.